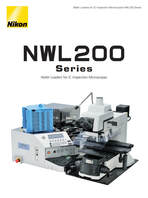

NWL 200 Wafer Loader Series

Product HighlightsHigh Reliability in Semiconductor ProductionWhen the power supply is interrupted unexpectedly, the vacuum chuck of the macro arm remains active, allowing safe wafer removal.

Macro Inspection FunctionsSemiconductor wafer front side pattern, back periphery and center area inspection is supported. The wafer rotation speed and tilt angle are set automatically or manually.

Designed for Maximum ThroughputA fast wafer cassette elevator with a non-contact centering mechanism allows rapid, accurate wafer alignment using a multi-arm system for loading and unloading wafers with the highest precision.

Ergonomic DesignThe NWL200 is designed ergonomically for ease of operation and control. Positioned at 35 degrees to the left, wafer in-slot location and full cassette exchange is easy.

Core FeaturesClean Room System Anti-Contamination MeasuresDust from friction in the vacuum clamping area, or due to impact when centering wafers or aligning orientation flats or notches, is minimized using an uninterrupted airflow. The NWL200 cover is made from stainless steel, preventing buildup of static electricity.

Wafer Sensing Functions for Collision AvoidanceThin wafers suffer significant distortion. If sensors are not effective, the wafer may be damaged by the transfer arm. Nikon's specification and arrangement of sensor beams accurately detects if a thin wafer in the cassette is distorted, aborting its collection.

Remote Access Web Server Support ToolConnecting to a customer’s LAN via a web browser wizard interface allows easy interaction to create and back up inspection recipes. Remotely writing optimized control recipes enables checking of wafer features in a fluid, uninterrupted workflow.

100µm Ultra-Thin Wafer ChuckChips are becoming ever thinner through advances in manufacturing, requiring handling of extremely thin wafers. The NWL200 Series loads ultra-thin wafers to a thickness of 300µm and 200µm as standard, or 100µm as an option.

Efficient Front Panel User InterfaceA single button selects any wafer from its cassette slot. The large LCD screen supports rapid interaction with the system controls and recipes. A structured menu permits easy user dialogue with the system.

Macro Inspection FunctionsSemiconductor wafer front side pattern, back periphery and center area inspection is supported. The wafer rotation speed and tilt angle are set automatically or manually.

Designed for Maximum ThroughputA fast wafer cassette elevator with a non-contact centering mechanism allows rapid, accurate wafer alignment using a multi-arm system for loading and unloading wafers with the highest precision.

Ergonomic DesignThe NWL200 is designed ergonomically for ease of operation and control. Positioned at 35 degrees to the left, wafer in-slot location and full cassette exchange is easy.

Core FeaturesClean Room System Anti-Contamination MeasuresDust from friction in the vacuum clamping area, or due to impact when centering wafers or aligning orientation flats or notches, is minimized using an uninterrupted airflow. The NWL200 cover is made from stainless steel, preventing buildup of static electricity.

Wafer Sensing Functions for Collision AvoidanceThin wafers suffer significant distortion. If sensors are not effective, the wafer may be damaged by the transfer arm. Nikon's specification and arrangement of sensor beams accurately detects if a thin wafer in the cassette is distorted, aborting its collection.

Remote Access Web Server Support ToolConnecting to a customer’s LAN via a web browser wizard interface allows easy interaction to create and back up inspection recipes. Remotely writing optimized control recipes enables checking of wafer features in a fluid, uninterrupted workflow.

100µm Ultra-Thin Wafer ChuckChips are becoming ever thinner through advances in manufacturing, requiring handling of extremely thin wafers. The NWL200 Series loads ultra-thin wafers to a thickness of 300µm and 200µm as standard, or 100µm as an option.

Efficient Front Panel User InterfaceA single button selects any wafer from its cassette slot. The large LCD screen supports rapid interaction with the system controls and recipes. A structured menu permits easy user dialogue with the system.